Description

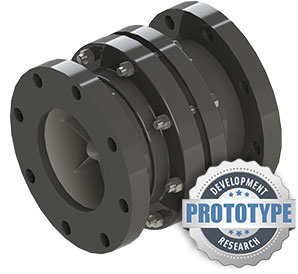

The C•Shell pump series is MDM’s new horizontal centrifugal product family designed for use in the Chemical Process Industry (CPI) and corrosive fluid handling markets. C•Shell products are a complement to MDM’s larger line of non-metallic, end-suction centrifugal pumps. C•Shell products are armored pumps consisting of metallic cast pump shells with a thermoset polymer non-metallic lining. As with MDM’s non-metallic Genesys and Advance products, C•Shell products have been designed to offer the highest efficiencies, lowest maintenance cost and longest life – for the lowest total cost of ownership. Oversized volutes offer high flows at low rotational speeds for nearly silent operation.

Mechanical seals are a Type 21 cartridge, offered in a wide range of seal materials compatible with different pumped fluids. The seal chamber design provides for easy and fast installation. The use of proprietary pump selection software enables MDM to tailor pump solutions to each system requirement, assuring optimum efficiency and highest return on investment for MDM customers.