Description

DESIGN

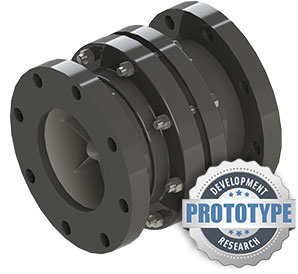

The Advance 4000 is a close-coupled, end suction centrifugal pump line which is molded in glass-filled polypropylene. Its high-efficiency design makes it suitable for medium flows [to 200 GPM] and higher heads [up to 80’ TDH]. When fitted with the patented Impenatra® Seal, the Advance 4000 provides total non-metallic contact, while maintaining the benefits of a direct drive unit.

The design of the pump, coupled with the chosen resins, produces a strong, durable, versatile unit. When used with the patented Impenatra® seal, the fluid pumped does not contact any metal parts. This allows it to properly handle many corrosive and chemical applications at a fraction of the cost of exotic alloys.

APPLICATIONS

Typical applications serviced by the Advance 4000 include transfer of chemical process fluids, filtration systems, deionized water transfer, wastewater reclamation, pressure spray systems, fountains, plating chemical transfer and recirculation, fume scrubbers, and pollution control equipment.

CORROSION RESISTANCE:

Here is a small sampling of the chemicals handled:

• Sodium Hydroxide (10%) • Ammonium Hydroxide (10%) • Sodium Bicarbonate (SAT.) • Ammonium Phosphate (SAT.) • Potassium Bicarbonate (SAT.) • Demineralized Water • Ferric Chloride (SAT.) • Ethylene Glycol • Acetic Acid (10%) • Nickel Plating Solutions

PERFORMANCE

Engineered for high efficiency, Advance impellers are enclosed to accommodate a wide variety of pressures and fluids. The standard impeller trims deliver the performances listed at 60 HZ. [3450 RPM]. Contact factory for 50Hz performances.

VERSATILITY

The pump can be close-coupled to a 56J motor or mounted to a bearing pedestal. Both single and three-phase motors in ODP and TEFC enclosures are readily available. An adapter kit is available to convert to a 56C flange. A variety of elastomers, seals, impellers, and motors can be combined to meet your exact requirements. All units are bench tested prior to shipping.

MARKETING

We are structured to sell unassembled pump ends, as well as completely assembled pump and motor units. We specialize in serving OEM’s and distributors throughout the world.

![]() ADVANCE 4000 DIMENSIONAL DRAWINGS

ADVANCE 4000 DIMENSIONAL DRAWINGS![]() ADVANCE 4000 DATA SHEETS (60 HZ)

ADVANCE 4000 DATA SHEETS (60 HZ)![]() ADVANCE 4000 INSTALLATION MANUAL

ADVANCE 4000 INSTALLATION MANUAL