Description

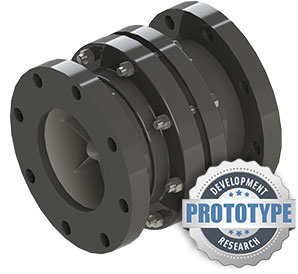

A unique, patented design in mechanical seals is available from Advance. The Impenatra seal is a radically new approach to solve many shaft sealing problems. When used with the Advance line of pumps, it isolates all metallic parts from contact with the fluid.

Alternately, corrosive chemicals require seals made of exotic alloys. The high prices and long lead times are objectionable. The Impenatra seal offers a solution to both problems.

TECHNICAL DATA

- Seal Type – Stationary spring, reverse mount

- Maximum Temperature – 194°F

- Materials of construction:

- Seal case – injection molded polypropylene

- Seal face – carbon graphite resin, binderless graphite or silicon carbide

- Seal seat – high purity ceramic or silicon carbide

- Elastomers – EPDM, Viton®, Kalrez® and Aflas®

WHAT’S DIFFERENT ABOUT THE IMPENATRA

- A proven, balanced design approach which eliminates hang up.

- Seal case is precision-molded of chemical-resistant thermoplastic.

- All metal surfaces, springs and shafts are isolated from fluid contact.

- Easily handles a wide range of chemical solutions including most acids, bases, and inorganics.

- Every seal is individually inspected to ensure consistent quality and is readily available.

WHAT THIS MEANS TO YOU

- Unprecedented corrosion resistance protects from attack by contained fluid and from the surrounding environment.

- Easy to install, field adjustment not required.

- Offers good versatility at an excellent price.

- Reliability, due to the simplicity of design and quality components.

EXAMPLE CORROSION RESISTANCE

- Deionized Water

- Ferrous Chloride 100%

- Hydrochloric Acid 37%

- Hypo Acid Fixing Baths

- Nitric Acid 10%

- Phosphoric Acid

- Photographic Developers

- Plating Solutions

- Sodium Hydroxide

- Sodium Hypochlorite

- Sulfonic Acid (aerated)

- And much more…

For a full list of corrosion resistant fluids click here.

![]() IMPENATRA SEAL CORROSION RESISTANCE CHART

IMPENATRA SEAL CORROSION RESISTANCE CHART